Home Foundation Repair in Billings, MT

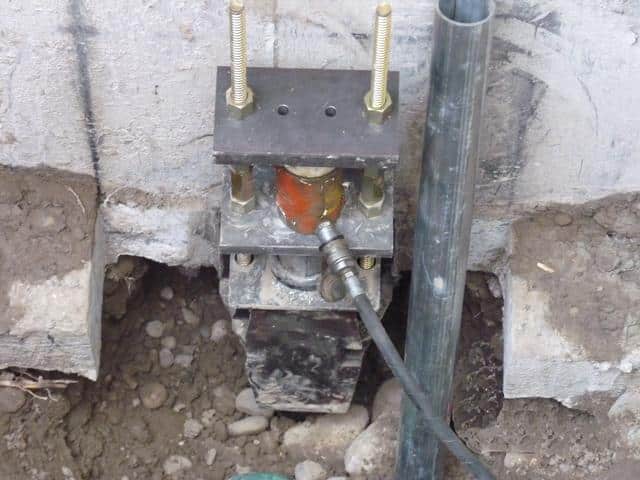

The owners of this home contacted YSS with structural issues concerning the foundation of their home. They received a level survey and report from Matt Krivonen of Krivonen Associates, Structural Engineers which indicated settlement along the West wall of their home. This section of the home was constructed on fill soils which had partially collapsed creating the foundation instability. YSS was contacted because being "highly recommended" by acquaintances of the home owners and the recommendation by the engineer. This project posed initial challenges due to the cantilevered main floor section which protruded nearly 2.5 feet from the main wall. This made excavation to the basement footing a work of precision. The foundation was excavated and exposed without causing any damage to the stucco exterior of the cantilevered main floor section. During excavation, the second major hurdle was discovered. For unknown reasons, an abandoned foundation (footing, stem wall, and grade beam footing) was discovered below grade and extended 2-3 feet from the actual end wall of the house. This not only made excavation more challenging, it also added complexity to the project. This abandoned foundation section was still connected to the house which increased loading and would act as an "anchor" while trying to raise the structure. YSS solved the problem by using a hydraulic concrete wall saw to cut the abandoned foundation free from the foundation supporting the home. The cuts were made diagonally so that not only would we isolate the active foundation but also to allow for upward movement during the lifting process. A total of 13 FSI Model 288 resistance piers were then installed to bedrock and the home was lifted and stabilized. Yellowstone Structural Systems performs foundation repair in the greater areas of Billings, MT, Missoula, MT, Cody, WY, and Powell, WY